Semi-dry desulphurization process

Flue gas enters the absorption tower from the air distributor at the bottom of the fluidized bed to fully mix with lime hydrate grains. SO2,SO3 and other harmful gases such as HCI and HF then react with lime hydrate to produce Ca SO3.1/2H2O

Reaction mechanism:

When the process water is atomized in the reactor after passing through the double fluid atomization nozzle, given full contact with flue smoke, cooled and humidified, calcium hydroxide powder particles will produce dry powder product after reaction with H2O、SO2、H2SO3. The whole reaction can be divided into three states of air, liquid and solid:

Ca(OH)2(solid)→Ca(OH)2(liquid)

SO2(air)+H2O→H2SO3(liquid)

Ca(OH)(liquid)+HSO3(liquid)→CaSO3(liquid)+2HO

CaSO3(liquid)→CaSO3(solid)

CaSO3(liquid)+1/2O2(liquid)→CaSO4(liquid)

CaSO4(liquid)→CaSO4(solid)

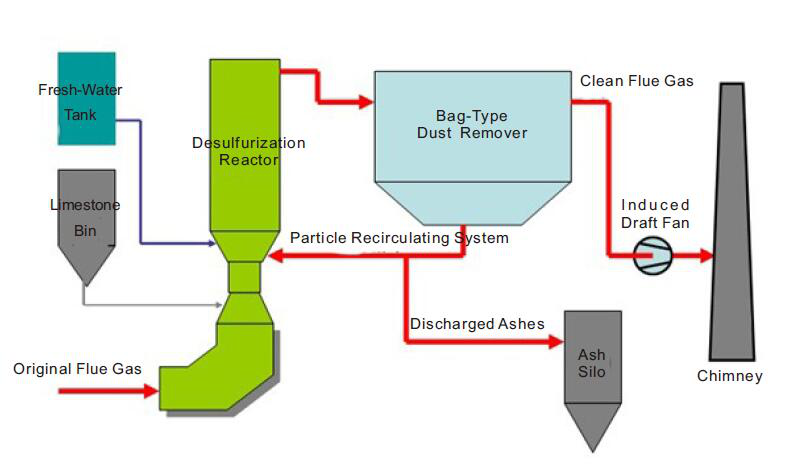

Process introduction:

The flue gas from the boiler enters the reactor from the bottom and blends with the absorbent which enters the reactor from the air trough and the recycled ash from bag dust removal in around Venturi tube. After the washing of jet stream in the Venturi tube, the flue smoke, absorbent and ash enter the straight tube of the reactor after full blending. There's a sprinkler at the flaring exit of the Venturi tube to reduce the gas temperature of the desulfuration tower to about 15 ℃ higher than the flue gas dew point with the atomized water from the sprinkler. On the condition of lower temperature and higher humidity, SO2 in the flue gas reacts with the absorbent to produce calcium sulfite and calcium sulfate. The treated flue gas enters the bag dust remover with lots of dry solid grains to be treated. Then the dry recycled ash will be separated from the flue gas by the bag dust remover to be transferred by the conveyer device to the reaction device to be recycled again. The temperature of the cleaned flue gas will not be lower than 15℃-its dew point, and it will be discharged into the chimney by the draught fan without being heated.

Characteristics of semi-dry desulphurization technology:

Strong adaptability to SO2 concentration change at the inlet

High desulphurization efficiency, up to 90%

Dry desulphurization by-product, easy for disposal; no sewage discharge and secondary pollution

Small system resistance, low operation cost and good economic performance for long-term operation

Small floor area, simple and reliable system, easy to be controlled

Advanced fluidized bed reaction tower design provides extremely good desulphurization reaction environment( temperature, humidity, concentration, flow filed, etc.) and optimal gas/solid velocity ratio so as to ensure best heat transmission and mass transfer effect.

Absorption agent is suspended and fluidized in the tower with the surface constantly updated so as to ensure high desulfurizing agent utilization ratio, effectively reduce Ca/S ratio and reduce desulfurizing agent consumption

Maintain best reaction temperature in the tower by water spraying. Meanwhile, secondary humidifying and activation can be conducted for absorption agent in the tower. According to flue gas amount, temperature and moisture content, multiple layers of water spraying can be set up. Each layer of water spraying can be controlled separately so as to ensure even sectional temperature inside the reaction tower.

Flue gas recycling system is set up to effectively adapt to boiler load change and to ensure good fluidized bed effect inside the tower.

Process schematic drawings